WEHRLI CUSTOM FABRICATION

WEHRLI WCF100367 2006-2010 LBZ/LMM DURAMAX 3.5" PASSENGER (COLD) SIDE INTERCOOLER PIPE KIT

- SKU:

- WCF100367

- MPN:

- WCF100367

- Shipping:

- Calculated at Checkout

Description

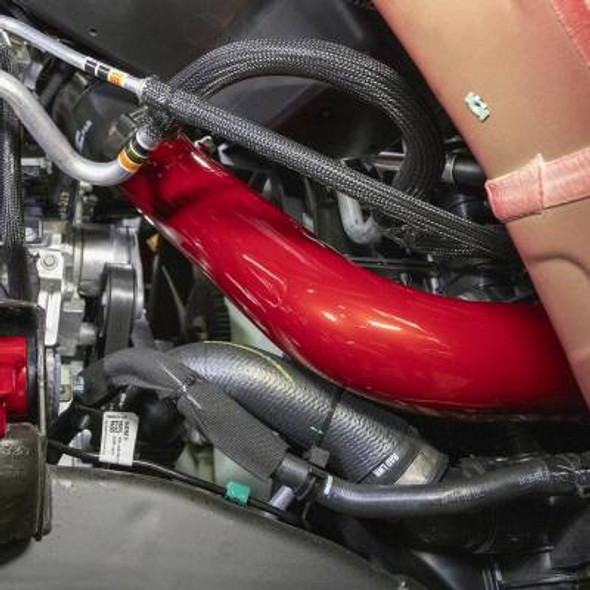

The 3.5" High Flow Passenger (Cold) Side Intercooler Pipe Kit for 2006-2010 LBZ/LMM Duramax replaces the failure prone factory plastic piece with a larger, high flow, 14 ga. aluminum fabricated 3.5" pipe. This part uses CNC machined flanges with double O-ring seals, comes supplied with a new wire clip rings for both slip flanges, and uses an upgraded silicone hump boot with stainless steel t-bolt clamps to withstand higher boost pressures than the factory components to increase reliability and eliminate blown factory boots and horsepower robbing boost leaks. Finished in your choice of custom powder colors. This pipe is compatible with stock trucks requiring no additional modifications, upgrades, or tuning for installation.

Improves airflow between the turbo and engine for improved efficiency, throttle response, and turbo spool up. Eliminates weak points in the factory design that can lead to boost leaks or complete failures in hard working and high-performance applications.

Installs easily with basic hand tools.

Replaces GM Part number: 15102148.

Pairs best with emissions compliant tuning and drop in turbochargers for optimum performance gains.

POWDER COATING - CHECK OUT OUR VIDEO

Powder coating has quickly become one of the most popular alternatives to traditional paint coatings. This type of surface finishing uses a dry powder applied electrostatically as a coating. The part is then cured in an oven for a period of time at temperatures ranging from 380-425*F to form a solid, durable finish. Powder coating not only looks great, but it also lasts longer while providing protection from harmful corrosion. To further improve corrosion resistance for components exposed to the weather we can first apply a Zinc-Rich Base Coat primer before the final color, which offers nearly ten times the corrosion resistance of just a standard coat of powder.

Wehrli Custom Powder Coating is housed under the same roof as Wehrli Custom Fabrication. Including 4 state of the art spray booths for both powder and ceramic coating applications and 6 curing ovens. Exceptional quality control, preparation, and packaging is our standard operation and what we have become known for. With over 30 different colors in stock at our facility, you have many options to choose from. If you don't see one you like, Prismatic Powders has over 5000 colors to choose from! (Non-stocked colors requested it will incur an additional fee) Below is a list of what we have in stock!