WEHRLI CUSTOM FABRICATION

WEHRLI WCF100235 LBZ/LMM DURAMAX HIGH FLOW 3" Y-BRIDGE (BRIDGE ASSEMBLY ONLY)

- SKU:

- WCF100235

- MPN:

- WCF100235

- Shipping:

- Calculated at Checkout

Description

***BRIDGE ASSEMBLY ONLY***

The factory LBZ/LMM Y-bridge is a poorly designed slip-in style two-piece bridge with very little support that is prone to blowing apart under boost and creating poor drivability and performance. This kit is a much improved, bolt together style two-piece 3" High Flow Y-Bridge designed to address the factory weak points for custom build performance and racing applications.

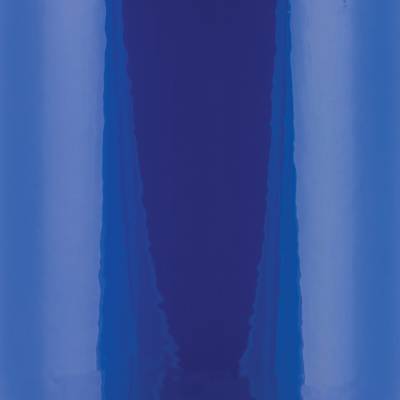

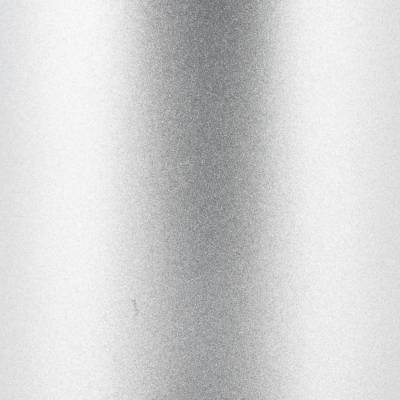

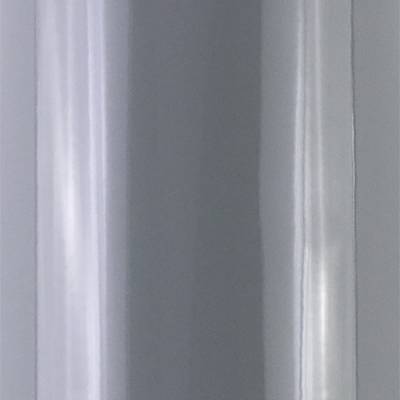

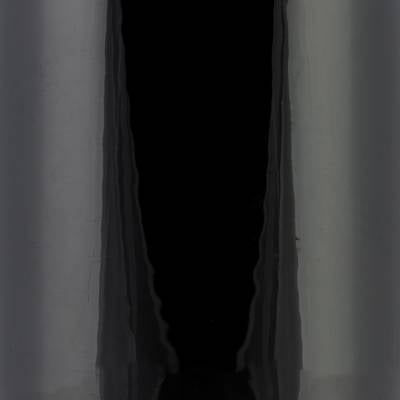

Bolts to OEM intake runners. 3" Bead Roll Connection at inlet. Easy to install two-piece bolt together design replaces separation / boost leak prone OEM part. Raw finish ready for polishing and painting standard. Custom Color Powder Coat finishes (as shown) are available as an optional upgrade and carry additional lead time.

***Designed for use with aftermarket and custom fabricated high flow piping and turbo kits running higher boost pressures. Not compatible with OEM piping, requires additional fabrication work / customization for integration with turbocharger intercooler system. ***

***NOTE: Raw finish selection will require some type of finish / sealant to prevent oxidation and corrosion***

POWDER COATING - CHECK OUT OUR VIDEO

Powder coating has quickly become one of the most popular alternatives to traditional paint coatings. This type of surface finishing uses a dry powder applied electrostatically as a coating. The part is then cured in an oven for a period of time at temperatures ranging from 380-425*F to form a solid, durable finish. Powder coating not only looks great, but it also lasts longer while providing protection from harmful corrosion. To further improve corrosion resistance for components exposed to the weather we can first apply a Zinc-Rich Base Coat primer before the final color, which offers nearly ten times the corrosion resistance of just a standard coat of powder.

Wehrli Custom Powder Coating is housed under the same roof as Wehrli Custom Fabrication. Including 4 state of the art spray booths for both powder and ceramic coating applications and 6 curing ovens. Exceptional quality control, preparation, and packaging is our standard operation and what we have become known for. With over 30 different colors in stock at our facility, you have many options to choose from. If you don't see one you like, Prismatic Powders has over 5000 colors to choose from! (Non-stocked colors requested it will incur an additional fee) Below is a list of what we have in stock!